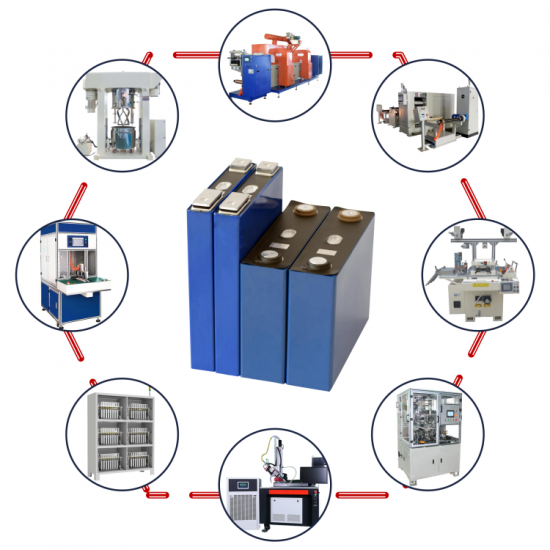

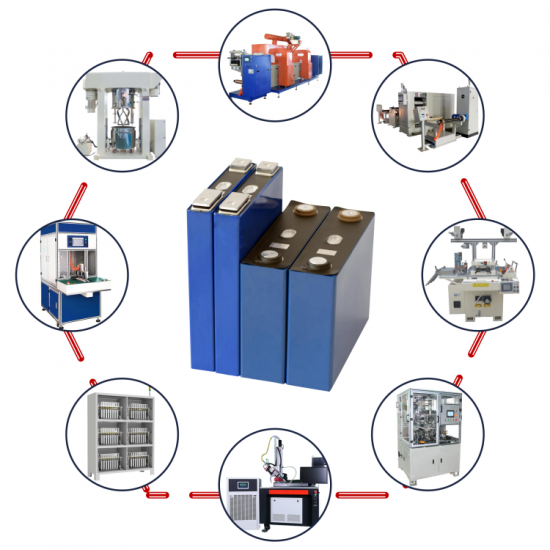

Prismatic Cell Fabrication: The Process and Technology

Prismatic cells are a popular lithium-ion battery format known for their rectangular shape, high energy density, and efficient space utilization. These cells are widely used in applications such as electric vehicles (EVs), energy storage systems, and consumer electronics. Fabricating prismatic cells involves a series of precise and controlled steps to ensure high performance, safety, and longevity.

---

● Key Steps in Prismatic Cell Production Plant

1. Electrode Preparation

- Mixing: Active materials (e.g., lithium nickel manganese cobalt oxide), conductive additives, and binders are mixed into a slurry.

- Coating: The slurry is uniformly applied onto a current collector (copper for the anode, aluminum for the cathode) using precision electrode coating machines.

- Drying: The coated electrodes are dried to remove solvents.

- Calendering: Electrodes are compressed to achieve a consistent thickness and improve energy density.

2. Electrode Cutting

- Slitting: Long sheets of coated electrodes are slit into narrower strips or cut into required shapes for stacking or winding.

3. Cell Assembly

- Separator Placement: A separator is placed between the anode and cathode to prevent short circuits.

- Stacking or Winding:

- Stacking: Individual layers of anode, separator, and cathode are stacked in a precise sequence.

- Winding: For some designs, the electrodes and separator are wound into a rectangular "jelly roll."

- Enclosure: The electrode assembly is placed into a rigid prismatic casing made of aluminum or steel.

4. Electrolyte Filling

- The casing is filled with a liquid electrolyte, which facilitates lithium-ion movement between electrodes during charging and discharging.

5. Sealing

- The cell is hermetically sealed using advanced welding techniques, such as laser welding, to prevent leakage and protect against environmental factors.

6. Formation and Aging

- Formation: Initial charging and discharging cycles are performed to form a stable solid electrolyte interphase (SEI) layer on the electrodes.

- Aging: Cells are aged to ensure stability and to identify any early defects.

7. Testing and Quality Control

- Cells undergo rigorous testing for performance, capacity, internal resistance, and safety to meet industry standards.

---

● Challenges in Prismatic Cell Fabrication

1. Material Uniformity: Ensuring consistency in electrode coatings for optimal performance.

2. Precision: Accurate stacking or winding to avoid misalignments.

3. Sealing: Achieving perfect seals to prevent electrolyte leakage or external contamination.

4. Thermal Management: Managing heat during assembly to avoid material degradation.

---

● Advantages of Prismatic Cells

- Compact Design: Efficient use of space for higher energy density.

- Scalability: Easy to stack or integrate into battery packs for larger systems.

- Structural Stability: Rigid casing provides better mechanical support.

---

● Applications

- Electric Vehicles (EVs): High energy density and robust design make them suitable for automotive applications.

- Energy Storage Systems (ESS): Reliable energy storage for renewable energy integration.

- Consumer Electronics: Slim form factor for compact devices.

---

Equipment Used in Prismatic Cell Fabrication

- Electrode Coating Machines: For uniform slurry coating.

- Calendering Machines: To compress electrodes.

- Precision Cutters: For slitting and shaping electrodes.

- Winding or Stacking Machines: To assemble the electrodes and separators.

- Electrolyte Filling Systems: For precise electrolyte injection.

- Laser Welders: For sealing the cell casing.

- Formation and Testing Stations: For charging, discharging, and quality control.

---

Conclusion

Prismatic cell fabrication is a sophisticated process that requires precision, advanced technology, and stringent quality control to deliver high-performance batteries. The resulting cells play a crucial role in powering the world's shift toward electrification and renewable energy solutions. If you're exploring prismatic cell manufacturing or need specific insights into the equipment, feel free to ask!

tr

tr en

en fr

fr de

de ru

ru es

es pt

pt ko

ko pl

pl th

th

ipv6 ağı desteklenir

ipv6 ağı desteklenir