Prismatic Cell Production Plant: Key Processes and Technologies

A Prismatic Cell Production Plant is a manufacturing facility where prismatic lithium-ion battery cells are produced. Prismatic cells are one of the most common battery types used in various applications such aselectric vehicles (EVs),energy storage systems (ESS), andportable electronics due to their high energy density, efficient packaging, and durability.

In this article, we will explore the main processes, equipment, and considerations involved in the production of prismatic cells, as well as their advantages and the challenges associated with scaling production.

●What is a Prismatic Cell?

A prismatic cell is a lithium-ion battery cell that has a rectangular or flat, box-like shape, making it ideal for applications where space optimization is important. These cells are typically encased in either metal or hard plastic housing, offering structural integrity and high energy density. Compared to cylindrical or pouch cells, prismatic cells are favored in large-scale energy applications such as electric vehicles due to their ability to be stacked efficiently.

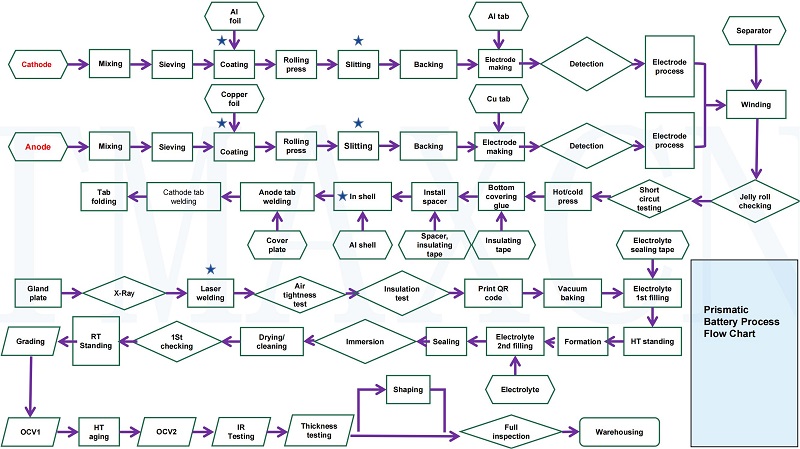

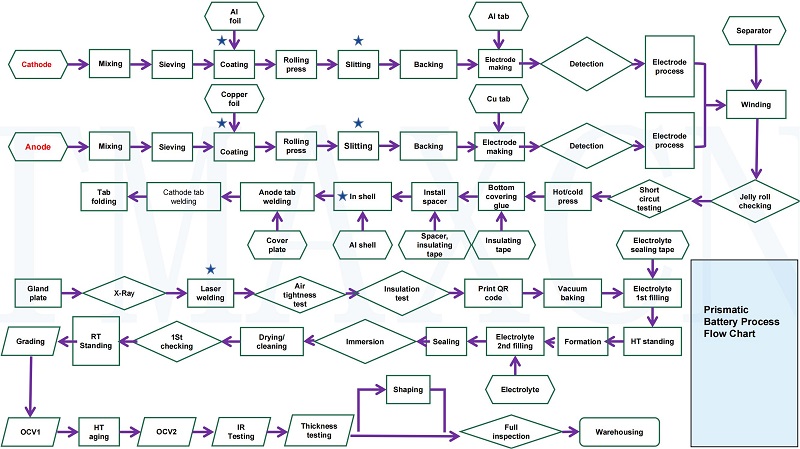

●Key Steps in the Prismatic Cell Production Process

The production of prismatic cells involves multiple steps that require precision, cleanliness, and advanced manufacturing technologies. Below is an outline of the main stages in the production of these cells:

1.Electrode Manufacturing

The first critical step in prismatic cell production is the manufacturing ofelectrodes (anode and cathode). These electrodes are the active components that store and release energy through chemical reactions.

-Mixing: Active materials (such as lithium nickel cobalt manganese oxide for the cathode or graphite for the anode) are mixed with binders, conductive additives, and solvents to create a uniform slurry.

-Coating: The slurry is evenly applied onto a copper or aluminum foil (current collectors) using anelectrode coating machine. This process ensures consistent thickness and smoothness.

-Drying: After coating, the electrodes are dried to remove any solvents. Drying ovens or vacuum chambers are used to ensure that the electrodes have the desired moisture levels.

-Calendering: The coated electrodes are passed through rollers to compress them and increase energy density. This process, known ascalendering, also improves the uniformity of the electrode surface.

2.Electrode Slitting and Cutting

After the electrodes have been prepared, they are cut into precise shapes that fit the dimensions of the prismatic cell. The cutting process needs to be highly accurate to ensure that the electrodes fit perfectly into the casing.

-Slitting: Long sheets of electrodes are slit into narrow strips of appropriate width for stacking or winding.

-Cutting: The strips are then cut into specific lengths, depending on the size of the prismatic cell.

3.Cell Assembly

The assembly process involves stacking or winding the cut electrodes into their final form, along with the separator material, to create the prismatic cell structure.

-Electrode Stacking/Winding: The anode, cathode, and separator are assembled in a layered or stacked arrangement. This process can be automated using high-precisionstacking machines that ensure even alignment and minimize defects.

-Electrolyte Filling: Once the electrodes are assembled, theelectrolyte solution (usually a liquid organic solvent with lithium salts) is injected into the cell. This electrolyte enables the movement of lithium ions between the anode and cathode during charging and discharging.

-Sealing: The prismatic cell is enclosed in a metal or hard plastic casing to protect the internal components and maintain structural integrity. The casing is typically sealed using heat, ultrasonic welding, or laser welding to ensure that no air or moisture enters the cell.

4.Formation and Aging

After the cells are assembled, they undergo aninitial charging process, known asformation, where the cell is charged and discharged for the first time. This step is crucial for stabilizing the internal structure of the cell and activating the electrolyte.

-Formation: The cells are subjected to a controlled charging and discharging cycle to form the solid electrolyte interface (SEI) layer, which protects the anode and ensures long-term stability.

-Aging: The cells are stored for a period of time (usually days to weeks) in a controlled environment to monitor their voltage stability and detect any early signs of defects.

5.Quality Control and Testing

Each prismatic cell is tested to ensure it meets stringent quality and safety standards before being released to the market. Testing includes:

-Capacity Testing: Ensures the cell meets its rated energy capacity.

-Leakage Testing: Verifies that there are no leaks in the casing or seals.

-Thermal Testing: Assesses how the cell behaves under various temperature conditions.

-Cycle Life Testing: Tests how many charge and discharge cycles the cell can go through before its performance begins to degrade.

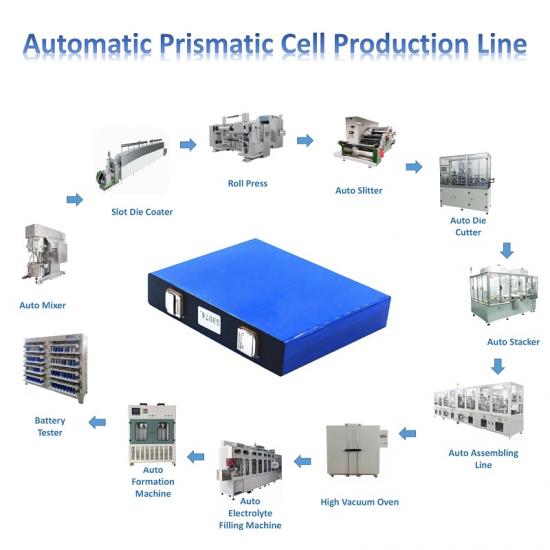

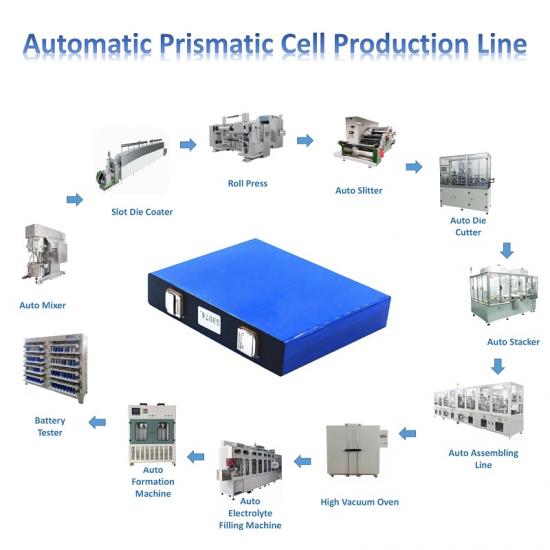

●Key Equipment in Prismatic Cell Production

-Mixing Equipment: For preparing the electrode slurries with precise composition.

-Electrode Coating Machines: For uniformly applying active materials to the current collectors.

-Calendering Machines: For compressing the coated electrodes to improve energy density.

-Slitting and Cutting Machines: For preparing electrodes to precise dimensions.

-Stacking and Winding Machines: For assembling the electrode layers into the prismatic cell format.

-Electrolyte Filling Machines: For injecting the electrolyte into the cell.

-Sealing Equipment: For closing and sealing the cell, often using laser or ultrasonic methods.

-Formation and Aging Equipment: For charging and aging the cells in a controlled environment.

●Advantages of Prismatic Cells

1.High Energy Density: Prismatic cells offer a higher energy density compared to other form factors due to their compact and efficient design.

2.Space Efficiency: The rectangular shape allows for efficient stacking and packaging, making them ideal for applications where space is limited, such as electric vehicles and energy storage systems.

3.Structural Integrity: The hard casing of prismatic cells provides better protection against physical damage and makes them more robust for high-demand applications.

●Challenges in Prismatic Cell Production

1.Manufacturing Complexity: Producing prismatic cells involves precise alignment and sealing, making the manufacturing process more complex and expensive compared to cylindrical cells.

2.Heat Dissipation: Due to the compact design, prismatic cells may have less effective heat dissipation, which can lead to overheating if not properly managed in applications such as electric vehicles.

3.Cost: The production of prismatic cells is generally more costly due to the specialized equipment and materials required for assembly and sealing.

●Applications of Prismatic Cells

1.Electric Vehicles (EVs): Prismatic cells are widely used in EVs because their high energy density and compact form allow for efficient space utilization in battery packs, leading to longer driving ranges.

2.Energy Storage Systems (ESS): Prismatic cells are used in grid-scale and residential energy storage systems to store renewable energy, such as solar or wind, for later use.

3.Consumer Electronics: Devices like laptops, tablets, and smartphones utilize prismatic cells for their thin and compact design, providing longer battery life in a smaller footprint.

4.Power Tools and Medical Devices: Prismatic cells are ideal for portable power tools and medical devices where durability, energy density, and compactness are crucial.

●Conclusion

APrismatic Cell Production Plant involves advanced processes and cutting-edge equipment to ensure high-performance and reliable battery cells. With their high energy density, robust design, and efficient space utilization, prismatic cells are at the forefront of applications like electric vehicles and energy storage systems. As demand for these batteries continues to rise, innovations in manufacturing and materials will play a key role in enhancing the scalability and cost-effectiveness of prismatic cell production.

tr

tr en

en fr

fr de

de ru

ru es

es pt

pt ko

ko pl

pl th

th

ipv6 ağı desteklenir

ipv6 ağı desteklenir